PUR (Polyurethane): Properties, Applications and Sustainability

Polyurethane (PUR) is a versatile and durable material widely used in various industries, including automotive, construction, and consumer products. With its unique properties, PUR has become an essential material in the plastics industry. However, the increasing demand for sustainable materials and eco-friendly production processes has led to a growing interest in the recycling of PUR waste.

The development of PUR dates back to the 1930s when German chemist Otto Bayer discovered the polymerisation reaction between diisocyanates and polyols. However, the commercial production of PUR did not begin until the 1950s, when it was used as a replacement for natural rubber in applications such as shoe soles and gaskets.

What is Polyurethane (PUR)

Polyurethane is a polymer composed of organic units linked by carbamate (urethane) links. The polymerisation reaction occurs between isocyanates and polyols, resulting in a material with a wide range of properties.

Material Properties of PUR

The properties of PUR depend on the type of isocyanate and polyol used, as well as the manufacturing process. Generally, PUR exhibits excellent durability, flexibility, and resistance to abrasion, impact, and chemicals. It can also be made into various forms, such as foams, adhesives, coatings, and elastomers.

Industrial Usage of PUR

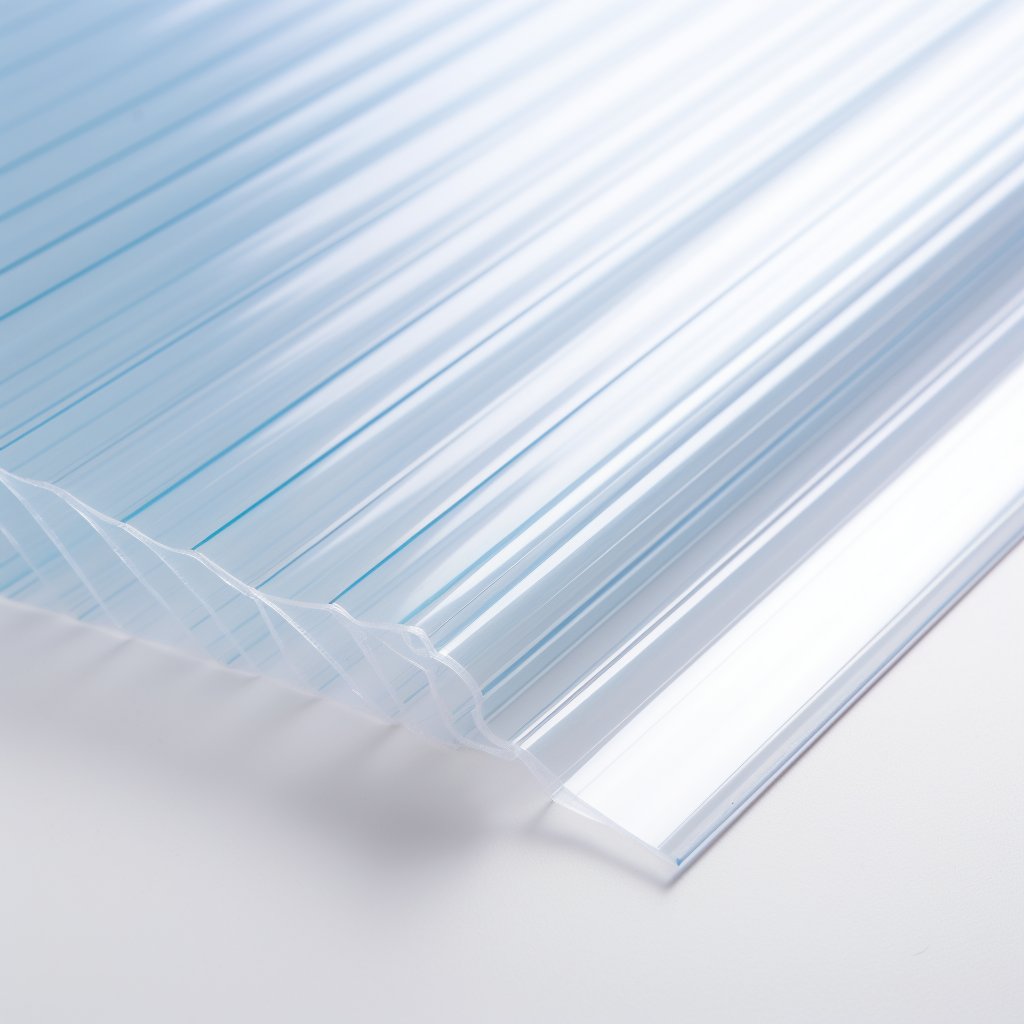

Today, PUR is widely used in various industries due to its unique properties. In the automotive industry, it is used for making car seats, dashboards, and steering wheels. In the construction industry, it is used as an insulation material and in producing doors, windows, and roofing. In the furniture industry, it is used for making foam cushions, mattresses, and upholstery. In the textile industry, it is used for making synthetic fibres, such as spandex.

Application Areas of PUR

PUR finds applications in various areas, including:

- Insulation: PUR foam is used for insulation in buildings, refrigeration units, and appliances due to its excellent thermal insulation properties.

- Adhesives: PUR adhesives are used for bonding various materials, such as wood, plastics, and metals.

- Coatings: PUR coatings are used for protecting surfaces from corrosion, abrasion, and chemicals.

- Elastomers: PUR elastomers are used for making seals, gaskets, and flexible parts.

Consumer Product Examples of PUR

Some of the consumer products that use PUR include:

- Footwear: PUR foam is used for making shoe soles, providing cushioning and support.

- Mattresses: PUR foam is used for making mattresses, providing comfort and support.

- Sports Equipment: PUR is used for making sports equipment, such as protective gear, helmets, and balls.

- Automotive Parts: PUR is used for making various automotive parts, such as seats, dashboards, and steering wheels.

Recycling of Polyurethane (PUR)

The recycling of PUR has been a challenging process due to its complex chemical composition. However, recent technological advancements have made it possible to recycle PUR waste, making it an eco-friendly material choice. The recycling process involves breaking down PUR waste into its chemical components and then using them to make new products.

Recycling PUR is a challenging process due to its complex chemical composition. However, several methods are available for recycling PUR waste, including mechanical, chemical, and energy recovery.

Mechanical recycling involves grinding PUR waste into small pieces and then using them as filler material in new products. This process is suitable for PUR foam waste, but it is not ideal for other types of PUR waste.

Chemical recycling involves breaking down PUR waste into its chemical components, such as isocyanates and polyols, and then using them to make new products. This process is more complex and expensive than mechanical recycling, but it is suitable for all types of PUR waste.

Energy recovery involves using the heat from burning PUR waste to produce electricity. While this process could be better for recycling, it is an effective way to reduce waste and generate energy.

Advantages of PUR recycling

- Environmental benefits: Recycling PUR waste reduces the amount of waste that goes into landfills and helps to conserve natural resources.

- Economic benefits: Recycling PUR waste creates new business opportunities and can help to reduce production costs.

- Energy savings: Recycling PUR waste requires less energy than producing new PUR products from raw materials.

Disadvantages of PUR recycling

- Cost: The cost of recycling PUR waste can be higher than the cost of producing new PUR products from raw materials.

- Complexity: PUR is a complex material, and the recycling process can be challenging, requiring specialized equipment and expertise.

Environmental and Global Impact of PUR Recycling

The environmental impact of PUR recycling is positive in that it reduces waste and conserves natural resources. However, the recycling process can also have negative ecological impacts, such as energy consumption and emissions from the recycling process.

Globally, the demand for sustainable materials is increasing, and the recycling of PUR waste is becoming more critical. In Europe, the recycling of PUR waste is regulated by the European Union’s Waste Framework Directive, which aims to reduce waste and promote sustainable resource management.

Advantages and disadvantages of PUR compared to alternative plastics

Advantages:

- Durability: PUR is a highly durable material that can withstand wear and tear, making it a popular choice for applications such as automotive parts, furniture, and textiles.

- Resistance to chemicals: PUR is highly resistant to chemicals, making it suitable for use in harsh environments such as the chemical industry.

- Customisability: The properties of PUR can be customised to suit different applications, making it a versatile material.

- Thermal insulation: PUR foam is an excellent thermal insulator, making it a popular choice for insulation in buildings and appliances.

Disadvantages of PUR compared to alternative plastics

- Cost: PUR is more expensive than some alternative plastics, making it less cost-effective for specific applications.

- Environmental concerns: PUR is not biodegradable and can take hundreds of years to decompose, which can lead to environmental concerns.

Market price developments

The market price of PUR has fluctuated in recent years due to various factors such as supply and demand, raw material prices, and global economic conditions. In 2021, the global polyurethane market was valued at $78.9 billion, with a projected compound annual growth rate of 5.5% from 2021 to 2028.

Future market prognosis

The future market for PUR is expected to grow due to the increasing demand for durable and versatile materials in various industries. With the rising awareness of sustainable materials, there will also be a focus on the development of eco-friendly alternatives and the recycling of PUR waste. Technological advancements will continue to drive the growth of new products and applications for PUR, further expanding its market potential.

Polyurethane

Polyurethane (PUR) is a valuable material with unique properties that make it an essential component in various industries. Its versatility and durability make it an attractive alternative to other plastics, but its disposal and environmental impact are challenges that need to be addressed. The recycling of PUR waste can significantly reduce its impact on the environment and promote sustainable resource management.

While recycling PUR is a challenging process, it is essential for reducing waste and promoting sustainable resource management. The advantages of recycling PUR include environmental benefits, economic benefits, and energy savings. However, the cost and complexity of the recycling process can be significant drawbacks. As the demand for sustainable materials continues to grow, the recycling of PUR waste will become increasingly important, and technological advancements will drive the development of new recycling methods.